ARE VARIABLE SPEED AIR COMPRESSORS SUITABLE FOR ALL FACILITIES?

When managers and executives look over their sites to find energy savings their compressed air systems always stand out. Compressed air is a necessary evil for many industries: a vital utility, but also a huge expense. As expensive as purchasing and maintaining an air compressor can be, the cost to power that compressor will be three times as much!

While there are many technologies on the market that can yield significant energy savings, many of these technologies have been developed for clean environments and cannot stand up to the excessive heat, dust, oil mists, or fumes, that are found in many environments. So before buying anything it’s important to understand how you can save energy without hampering reliability.

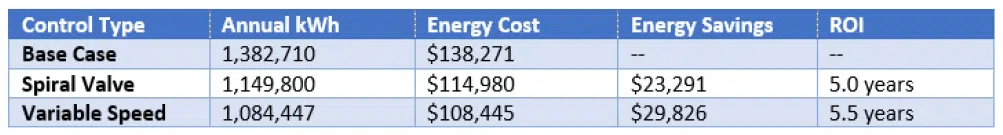

The most common type of industrial air compressor is the lubricated rotary screw. These are oil-injected, positive displacement compressors, designed for very little mechanical wear or internal corrosion. At full load flow, the specific power is typically 17 kW/100ACFM at an operating pressure of 100 psig, but when partially loaded the specific power will depend greatly on the compressor control system. The following graph compares the performance of four different control types from 0% to 100% full load flow.

This graph clearly shows that variable speed compressors offer the best part-load performance of the four control types. These compressors use a variable frequency drive (VFD) to vary the speed of the compressor’s main motor. However, it should be considered whether this is appropriate technology for the conditions at your facility.